Today has been the most practical sort of day, spent sorting and organizing gut. The bane of the workshop is the clean-up. I realize that no one likes to clean, but cleaning is especially problematic in a production workshop where the emphasis is on, well, production. This is a particular problem around the polishing machines. Numerous issues can arise when polishing a string. It is not uncommon for the stones to hit a rough spot and cut the string, or, which is very common, the string does not polish completely smooth, and needs to be set aside in favor of another, more promising-looking rough string. The result is that strings of odd gauges and lengths pile up on the bench and need to be dealt with occasionally, and today was one of those days. We have a new worker starting on Monday, and I want him to begin with a clean bench. So, as Boss of Gamut Music, it is my task to clean up after the last worker to create an unspoiled environment for the new one. Every new worker deserves a clean slate.

365 Days of Dan: Day 5

I have been making a lute bridge today, which has me thinking about bridges. Most of the very early lutes, especially the longed-neck lutes from Ancient Egypt, Elam, Iraq, Byzantium, etc., have bridges held in place by the strings, which terminated at the end of the instrument. Although a few images of Egyptian instruments from the 18th Dynasty seem to have bridges glued onto the fronts, most styles of ancient makers chose to connect the string tension to the instrument's body rather than have it stop at a fixture glued to the front. After seeing the vihuela E.7048 In the Cité de la Musique in Paris, I can understand why. String tension has caused the bridge to come off that instrument many times, judging by the condition of the front. The early Persian ʿūd makers came from a tradition of instruments that had strings fixed to each end, but they chose to develop a design where one end of the string terminated at a fixed strip of wood glued to the front. I can see trying that once, but doing it twice and then developing a whole musical heritage around the design? It was an interesting decision.

365 Days of Dan: Day 4

Today is an infusion day for me, so only a little workshop work is getting done. The time is still there, however, as it gives me time to reflect. Working on the Stainer violins brings to my mind learning how to "copy" or model existing instruments. Of course, that is the cornerstone of lutherie, as we all long to attach ourselves to a legacy, and an easy way to claim that is by copying instruments that represent a valued tradition. The first instrument I measured in 1973 was the Stainer violin in the Ashmolean Museum in Oxford, UK. In those days, our tools for technical measurements were limited, especially for a poor student, and I went to the museum with only pencils, a pad of paper, a divider, and a ruler. Owning a camera wasn't even a dream for me yet, so I hoped my rudimentary drawing skills and memory would be enough to create a record. When more sophisticated tools became available for documenting instruments, I wondered how accurate my ancient rubbings were when compared to the ultra-accurate drawings taken from CT scans. The image today shows a comparison of my original paprubbing taken from the Ashmolean Stainer violin in 1973 with the drawing of the Stainer violin published by the National Music Museum, Vermillion, SD, USA. Although the lines represent different instruments, my old hand tracing is remarkably similar to the computer line. Considering the primitive tools we used, I think we did an excellent job of making accurate reproductions of instruments.

365 Days of Dan: Day 3

Fitting a lute front into place does not look impressive, but this step determines the heart and soul of the instrument. The neck angle is set at this point, and the front relief is established. The centerlines of the body and front are matched, and the bridge's height is resolved.

The process requires putting the front in place dozens of times. Between each fitting, the struts are trimmed, the ribs are planned, and the neck angle is adjusted. Eventually, everything will be perfect, and the parts will be transformed into a harmonious whole.

365 Days of Dan: Day 2

The workshop is closed for the New Year holiday, and I always take this as an opportunity to close out the records of the old year and prepare the files for the upcoming year. It is quiet in the shop while everyone is home for the day, so I can catch up on some jobs without interruption. One task was to put the last two struts on a lute front, the short ones that support the rose. I always enjoy gluing those in place, as they represent a transition between the completion of the front and the assembling of the body. When they are dry, I can trim the struts to fit into the back, and after that task, it is a short time to have the instrument together. Those last two little struts are quite a milestone for me.

365 Days of Dan: Day 1

It is January 1, 2023, which marks my intention to initiate a daily post concerning the events in my life and that of Gamut Music.

I first walked into the London College of Furniture on September 17, 1972, which means I am in my fiftieth year as a luthier. Because of the string making, many people forget, and some don't even know that I started life as a violin maker. Although most of my recent time has been spent making lutes, I still work on violins in my home workshop on weekends and other time away from the Gamut workshop. My current violin project is a series of three instruments modeled on Stainer. One will have an early 17th-century setup, another will have a late 17th-century setup, and the third will have a mid-18th-century form. The first of this series is on the bench now.

Review of Ornythology: Byrd and Friends

Venere Lute Quartet Gamut Music GM04

Lute ensembles are such a rarity — only a handful of such groups exist — that any new recording of music for lute ensemble is worth celebrating. When that CD is an addition to the catalog of the Venere Lute Quartet, it is a special occasion for lute enthusiasts.

Founded in the early 2000s, the Venere Lute Quartet — Douglas Freundlich, Gail Gillispie, Christopher Morrongiello, and Phillip Rukavina — are something of an institution now: this is their fourth CD, and the ensemble has been a regular feature at LSA gatherings for many years. Ornythology is a welcome addition to the very small catalog of music for lute ensemble.

The quartet performs on matched instruments by Vancouver luthier Grant Tomlinson. These lutes are modeled on originals by Vendelio Venere, and closely akin to each other by design and scale. They are meant to be played in ensemble, and in the hands of four friends with a long experience of making music together, produce such a uniform “concord of sweet sounds” that at times one has the impression that a single instrument is being performed upon. All of the quartet’s instruments on this recording are strung with natural gut strings by Dan Larsen’s Gamut Music, Inc. The album was issued by Gamut as well, part of their small but growing catalog of high quality early music titles.

Ornythology is recorded with a very clear stereo image that spreads the four performers across the listener’s perceived aural space. When listening on headphones or in a room with speakers separated correctly to clearly project stereo, the impression is that the quartet sits before you: bass, tenor, alto, and descant lutes from lowest to highest, left to right. The album is beautifully recorded, evoking an acoustically resonant yet intimate environment: Duluth’s historic Sacred Heart Music Center.

All of the music hails from late sixteenth- and early seventeenth-century England, arranged for lute by and for the quartet. Much, or at least some of this music will be familiar to lutenists and even perhaps to the casual early music enthusiast. While the emphasis is on music by William Byrd (ten of the CD’s twenty-one tracks), other composers represented include Thomas Tallis, Alfonso Ferrabosco, Orlando Gibbons, and Thomas Morley, as well as six pieces by John Dowland. Friends indeed!

The selections chosen comprise a program balanced between pieces that were originally either choral works or dances, and although the music is arranged from a variety of original sources including works for keyboard, choir, and viol consort, it all sounds natural and “at home” in arrangement for lute quartet. Chestnuts like Tallis’s “If Ye Love Me,” the English country dance classic “Sellinger’s Round,” and Dowland’s “Captain Digorie Piper his Galliard” alternate with less familiar tunes. In a few cases (notably Byrd’s “Emendemus in Melius”) the quartet takes a brisker tempo than a choir would when performing the choral works, likely due to the lute’s inability to sustain long-value notes to the extent singers are able to. The resulting performances make a slightly different impression emotionally than sung performances do — very interesting listening for those who are familiar with the originals as vocal music.

As any lutenist knows, one of the difficulties of ensemble playing with rhythmic precision when you play a plucked string instrument is that compared to our bowed strings brethren, we have nowhere to hide! Everyone must be perfectly together. And that is perhaps the finest quality of this and the Venere Lute Quartet’s other recordings: a unity in performance that rings true from beginning to end.

Walter Bitner

"Ornythology: Byrd and Friends." Lute Society of America Quarterly, Volume 53, No. 4, Winter 2018

Baroque Music Reduces Stress

A study was presented to the 4th International Conference on Education, Economics, and Humanities on September 6, 2016, that was designed to study the effects on Baroque music as an agent for relieving stress.

In the study there were sixty Iranian ESL, (English as a second language), students that participated in a reading comprehension test while listening to Baroque music. Then, another test called the Test Anxiety Inventory (TAI) was administered to the group.

The resulting analysis revealed that listening to the music "had a significant effect on reducing reading test anxiety."

If you would like to read the whole report including the methods and statistical results, please follow this link.

Nylon Winding for Academie Contrabass Strings

We released the Red Diamond strings a few months ago and there has been a terrific response to the construction. Due to the popularity of the Red Diamond wound G-1 and D-2 strings, we have decided to add this option to the regular Academie line of bass strings.

Lyon Gut Wound With Nylon

This nylon makes the strings more durable, especially if you live in a high humidity environment or have an acidic perspiration. The nylon covering creates a protective layer that stops the gut fibers from becoming loose, causing the gut to break down and become false. This treatment will add some extra life to the string.

The Nylon is wound onto the Lyon gut of the G-1 and D-2 strings creating a transparent layer of protection to the gut. There is no need to oil the strings, making them a trouble-free way to have reliable and dependable strings on your instrument.

Go to the Academie Contrabass D-2 string page through this link.

Go to the Academie Contrabass G-1 string page through this link.

Detail of the Nylon Wound Lyon Gut

Student Discounts

We have received several messages from students recently asking if there is any way to receive a price break on strings to accommodate the financial straits that usually come with being a student. The answer is, yes, we do have a student discount program; it is just that not many folks know about it. So, this oversight shall be now corrected, please pass on the information to any students that you know.

All you need to do is create an account for our store (with your name, email, and address), then send a message to: support@gamutmusic.com requesting to be put on the Student Discount list along with a photo of your student ID. You will be added to the Student Group in the store and then, when you log into your account at shop.gamutmusic.com, all of the prices will be presented at a 15% discount!

Just so that the list is kept current, on September 20 of each year we clear out the names, but you can send another message with your current ID card and have another year of 15% discounts.

Rumors About Beef Gut

It has come to my attention in recent months that there are some rumors making the rounds about our beef gut supplier. I have received conflicting stories, but the gist seems to be that the workshop in Ireland that supplies us with material mishandles the gut by not removing the musose layer from the casing, which results in introducing non-muscle fibers into the strings, weakening them.

In defense of our supplier, and to reassure our customers that there is no problem with our strings, I thought I would explain a little about how the anatomy of the cow intestine works so that I can demonstrate how this rumor is not accurate to the quality of material and strings.

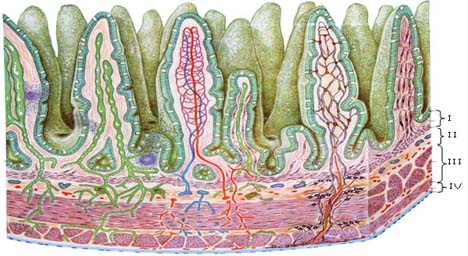

Below is an illustration of the four layers in the wall of the bovine intestine.

From Inside:

I - Mucose membrane with finger-like outgrowths for enlarged surface area (“slime”)

II - Submucose membrane, firm-elastic layer mainly of connective tissue

III - Muscular layer, the circular internal one, the outside one longitudinal

IV - Serose membrane (blue) thin coating covering the abdominal cavity from inside and surrounding all organs

____________________________________________________________________

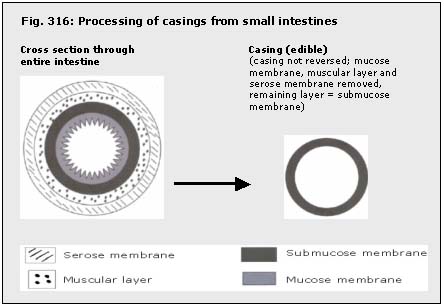

In cross-section, the layers are represented in the diagram below:

In processing the bovine casing for string production, the intestine is split lengthwise into ribbons. The ribbons can vary in width according to the needs of the string and when we order from the supplier, we order the ribbons, or threads, by width and the width needed is determined by the diameter of string we intend to make, the wider threads going into thicker strings and the more narrow threads going into smaller diameters.

As the gut comes off of the splitting machine one of the workers separates the mucose and submucose layers from the muscular and serose layers, as can be seen in the video below from the Gamut YouTube channel:

The muscular and serosa layers are very tightly bound together. It is difficult, but possible, to separate these layers and it is my understanding that some makers in the past have done this prior to twisting the strings. However, we here at Gamut Music are dictated to reproducing historical strings and no less an authority of strings making than Marin Mersenne was quite clear about which layers of the intestine should be used in string making when he made the comment about the habits of string makers:

“But they soak them (casings) a day before winding them upon their pegs, so as to clean them and to draw off the fat and all that is superfluous, and so as to leave the membrane alone, of three sorts of fibers, that is, the straight, the transverse, and the oblique, from which it takes its strength, …)

It is the three layers described in the illustrations that correspond to the three layers that Mersanne specifies as being critical to the strength of a string.

In short, the rumors criticizing our supplier are completely unfounded and are circulated, I suspect, by people that do not fully understand the process of making strings.

Please be assured that we and our suppliers are diligent to continue the tradition of making quality strings in the traditional way. When something goes wrong with a string, perhaps the material has something to do with it, but most probably, it is the string maker that has done something wrong. As we say in the workshop, “strings happen.”

These pictures come from the FAO Corporate Document Repository, produced by the Regional Office for Asia and the Pacific, www.fao.org.

This diagram also comes from the FAO Corporate Document Repository, produced by the Regional Office for Asia and the Pacific, www.fao.org.

Marin Mersenne, Harmonie Universelle: The Book On Instruments, translated by Roger E. Chapman, Martinus Nijhoff / The Hague, 1957, page 17.

String Workshop Update

Several of our customers have asked about the upgrades we have made to the string workshop to insure quality, so I thought I would put in a short description of the changes we have made to insure that you receive the best natural gut strings that we can make.

I have been in close contact with our suppliers to impress upon them the necessity of very high quality gut to start with. We got in a supply of sheep gut from Egypt, but it is less promising than the samples they first sent us. The strings are very strong, but there are numerous casings with irregular qualities that make it unsuitable for strings. I am disappointed that the yield is not more per hank, which drives up the cost of strings. However, I have found a new supply of lamb gut from New Zealand that looks promising. The strength is as good as the Egyptian gut and the yield is more per hank.

We have put in a new water softening system in the twisting workshop that also includes a carbon filter that removes chlorine and other chemicals, so we have the most pure and pH neutral water possible for making the strings. This allows us to control the processing of the gut more completely with confidence that there will be no reactions in the water with the chemicals we are using.

The drying cycle for the strings has been extended to 48 hours to insure that the collagen in the strings bonds thoroughly and make the strongest strings possible. We have also put in some extra environmental controls to maintain a more even humidity through the twisting and drying processes.

The strings are being seasoned for at least two weeks after the drying cycle before they are made into strings, and in most cases longer than that. We now color-code the batches so that we can use the oldest strings for each order and, if a problem does develop with a batch, we can easily purge that batch from the stock.

More and better testing is taking place with each batch of strings to check on the strength and durability of the batches.

The standard for gut strength is expressed as the breaking tension and the surface area of the cross section of the string, as Kilograms of tension decided by the surface area: Kg/mm².

There are two types of strength tests that are done on gut; one is called Knot-Pull, which tests the tension at which the string will break when knotted, and the other is the Straight-Pull test where the strength of the straight string is established. Gut strength is usually expressed from the Straight-Pull figures and suture makers of the 20th century established the standard of about 50 Kg/mm² for beef gut and about 40 Kg/mm² for sheep gut.

The tests on our current beef gut production focus on the Straight-Pull test and we are getting between 50 Kg/mm² and 56 Kg/mm² and the sheep gut is testing between 40 Kg/mm² and 45 Kg/mm².

In musical terms, this means that a beef gut violin e-1 string of .62mm will break at about “g” about “b” about the violin “e” and a .62mm sheep gut string will break at about “g#” above the violin “e.” This is a pitch of a-440.

Gut is a funny material and the changes and tests we are doing help a lot to insure quality, but, still, some strings will break as is the nature of gut. Please be assured that we are doing everything we can to reduce this possibility.

The Future of Englemann Spruce

In January of this year Jake and I took a break from the refreshing Duluth winter and went out to Anaheim, CA for the National Music Merchandiser’s trade show, otherwise known as NAMM. Among the more interesting conversations we had with a myriad of vendors was one we had with a long time wood supplier. I have been buying wood from him for many, many years as an independent wood dealer and now he works for the much larger organization, North American Wood Products in Portland, ME.

He has been my main source of Englemann Spruce from the Vancouver area, (the very best source for this material), and I was interested to talk to him about arranging a new shipment. Alas, I was informed that this material was not available any longer. Wood harvesting, as it turns out, has its fashions just like every other industry and currently, Englemann spruce is out of fashion. What the wood harvesters are cutting now is mostly Sitka spruce because this is what the guitar makers are interested in and it is the guitar industry that drives the supply and demand for a lot of the wood, especially the front wood that we use in early plucked instruments. This is an interesting turn of events in the sourcing of domestic tone woods.

We do have quite a bit of Englemann spruce in stock, but the word I am getting is that it will be harder and more expensive to obtain this wood going forward and, although I do not plan any price rises at the moment, the decreasing availability of this material going forward might necessitate some higher prices in the future.

The rise in popularity of Sitka spruce and greater availability is not necessarily good news for lute players. Although we have used this material successfully and made some really nice sounding instruments with it, it is a difficult wood to work with, especially to cut roses into, and has never been very popular with lute players.

Problems with Treble Gut Strings

Animal gut is an odd material for making strings and I have always thought that is is remarkable that any string can be made from it at all.

However, recently there have been some problems with treble gut strings — both beef and sheep — that have resulted in many strings breaking, some even before they got up to pitch. As you can imagine, this has been alarming to both us and the customers concerned and we have spent the last six weeks or so trying to sort it all out.

It looks like there have been several problems that came together at once. One was a problem with the treatment of some gut last autumn at the workshop of one of our suppliers that resulted in weak gut that we use specifically for making treble gut. Another problem has been with the continuing difficulties with the quality of sheep gut, and these challenges were compounded with a complication in the drying cycle in the workshop and another is that we have been releasing strings before they were fully cured and the result has been that some strings reached customers that were not good.

We have identified the poor quality gut and that material has been thrown away. In addition, we have made significant changes to the workshop that will give us better control of the environmental conditions for better string making. Also, we have found what we hope will be a better source of sheep casings from the Middle East and we are working on importing some of that material now.

In our efforts to get orders to customers as quickly as possible, we have been cutting strings off of the racks and polishing them before an adequate seasoning time had elapsed. Our production is rather small compared to other workshops and with the increase in demand for the strings over the last year or so, I have let the quality control slip a little. Consequently, to make sure we send out better strings, we are going to have to season the batches a little longer before the finishing stage of production.

In addition, we have started testing many more strings from each batch for tensile strength and general quality. Because of the nature of the material, each string will have certain individual characteristics, but we have developed a method of ascertaining the overall quality of a batch and we have a new method of following the batches through the finishing process.

These efforts will not solve all problems with all strings, as the nature of the material works against this goal, but we are confident that these efforts will help to minimize problems with strings going forwards. I believe that all of the suspect strings have been pulled from the stocks and disposed of, and what we will be sending out from now on will be good strings.

If you have had difficulties with treble strings recently, please let me know and you will receive replacements free of charge. If you have any difficulties going forward, please let me know and we will do what is necessary to resolve the problems.

Please note that with the new production schedule we might not have every string ready to send out at the time you place an order. Now, more than ever, it will be necessary to order well ahead of time to make sure strings get to you when you need them.

If you need replacement strings. please contact: support@gamutmusic.com.

Pegs for Viola da Gamba

April 19, 2022 – Due to manufacturing and supply constraints mechanical pegs are currently unavailable.

Gamut Music is expanding the parts and accessories all the time and our most recent addition is pegs for the viola da gamba family of instruments.

We now have in the catalog ebony pegs with boxwood collars and end decorations. The pegs are perfectly sized for the treble, tenor and bass viols and are made to a 30:1 taper which will fit all standard violin / cello peg reamers.

On the individual catalog pages you will find line drawings that specify the basic dimensions of each peg size. The pegs are beautifully finished and polished, ready to fit into your instrument.

New models will be added over the next few months, so check the catalog occasionally to see the latest style.

Results From The Dolmetsch Lute Auction

It is not often that a significant lute becomes available on the open market, but such an event took place on Thursday, June 6 at 11:00AM local time in New Zealand. The instrument in question was a fourteen course instrument made by Arnold Dolmetch. The hand written label in the instrument reads: “This is the first lute made at Jesses, Haslemere, under my direction. 1917 Arnold Dolmetsch.” The instrument is in a wooden case that has a number of shipping labels on it including a label with Diana Poulton’s name on it. There is little known about the instrument and how it got to New Zealand and the only information that the auction house had is that it was placed in a storage locker in 1993 in Wellington, New Zealand, and the locker has been delinquent for a long time, so the owners of the unit have sent the instrument to auction to recover some of the money owed on storage fees.

This lute, being, apparently, the first one made at the Dolmetsch workshop in Haslemere makes it one of the first lutes made in the lute revival of the 20th century and therefore a touchstone for the lute culture that we now enjoy.

It seemed important that this instrument be returned home to England and that it be made available for public view to be part of the historical record of the development of the lute revival in the 20th century. So, Dan, in his capacity as the President of the Lute Society of America, approached the Lute Society in England to see if there was any way to retrieve the instrument. As it turned out, the Horniman Museum in London was interested in the instrument, so the Lute Society and the Lute Society of America decided to pitch in and help. They made an appeal to members for donations to allow the Horniman Museum to purchase the instrument for its collection.

The Lute Society of America was able to collect $3,260 and this, together with the money that the Lute Society raised, was enough to allow the Horniman Museum to make the purchase and pay for all of the permits, shipping, etc. to bring the instrument back to England. The instrument will now become part of the permanent collection and be on display so that all can see the origins of the lute in the 20th century.

Thanks to everyone who worked to make this purchase possible.

Pictures of the instrument can be found following this link.

Mechanical Pegs Now Available at Gamut Music

April 19, 2022 – Due to manufacturing and supply constraints mechanical pegs are currently unavailable.

It is rare for there to be a technological advance in historical instruments but there is a great advance now available from the Peghed Company in the form of a geared lute peg.

Mechanical pegs represent a revolution is lute tuning. Each peg shaft is constructed with a planetary-gear mechanism that allows very fine tuning of the string. The gear has a 4:1 ratio which means that the peg head needs to be turned four times for the shaft to complete one revolution around. The peg also has a break mechanism so the string will tension not turn the peg and each has variable friction so you can push the peg into the peg box to increase the resistance or pull it out to decrease the resistance.

These pegs are exactly the same weight as an ebony peg, so they don’t make the instrument heavy and unbalanced and they fit into the same holes as a standard lute peg. You can only tell the difference between the mechanical peg and a friction peg if you look very closely.

These pegs offer several advantages over traditional, friction pegs: primarily, they don’t slip and allow a string to go slack and require re-settling. They also allow for tuning in extremely fine increments allowing for more accurate and easier tuning. All of these features are good; but the biggest advantage is that they require little effort to turn and your hand does not become strained while tuning. This can make your left hand more relaxed for playing and that can make the difference between a good performance and a bad performance.

If the old story, that a musician that has played the lute for thirty years has spent fifteen of them tuning is true, then using the mechanical peg could reduce that to a few years and provide you many more years of actually playing during your career with the lute.

These pegs are expensive but they will save you many hours of frustration in tuning your instrument.

Compared with other types of pegs, the Peghed is a little heavier, and the relative weights of different types of pegs are below. These are average weights taken from pegs with 9cm shafts.

Rosewood - 3.7g

Ebony - 4.1g

Boxwood - 3.3g

Peghed - 7.2g

When making an instrument that will utilize the mechanical pegs it is easy to lighten other parts of the head so that there is no resulting net gain in the weight or balance of the instrument when gears are used.

Peghed geared lute pegs are now available as an option for all Gamut Music guitars and vihuelas. Please consult the instrument pages in the catalog for pricing.

Aquila Stops Gut Production

Much of the Early Music world is buzzing about the recently announced closing of gut string production at the Aquila String company in Italy, and several musicians have contacted Gamut Music with concerns about the supply, quality and availability of gut strings. I would therefore like to reassure our customers with this explanation of the situation as I understand it.

Aquila posted a notice on their web site stating two reasons for the decision to stop gut string production: the first is the bad quality of raw material, and the second is European — and specifically Italian — regulations concerning the transport and use of gut. In this posting they specifically mention beef gut and no mention is made of sheep gut, leaving us with no understanding how of these issues effect that material.

As to the first issue: It is always a struggle to find quality materials for making gut strings. The fact is that gut supply is limited at the moment. Due to general worldwide economic conditions, droughts, low agricultural prices and increased demand, there is greater pressure on the supply of raw materials, but good gut is still available. Here at Gamut Music, we work and invest constantly to find the best material for strings and I can assure you that fine quality material is in our workshop at the moment. It is more expensive and might become more limited, but among our suppliers it is still available. I would also like to stress that markets ebb and flow and I am confident that, as conditions change, the price and availability of materials will become easier. We are just experiencing a tough time at this moment.

As to the second issue: I don’t know the specific rules that control the regulations of animal casings in Italy, but I have a general understanding of the regulations concerning the production and use of casings and serosa in the European Union and I have discussed these issue with other European string makers and gut suppliers and here is what they have told me.

In Europe there is no restriction on the trade and use of sheep gut.

There are, however, some regulations on the use of beef serosa, but if you have a licensed Technical Plant you can transport and use beef serosa under that license without restrictions.

My understanding from talking to others is that there may be trade restrictions in Italy because the Italian authorities want production materials to come from domestic sources rather than abroad and the regulations have more to do with Italian domestic protection than anything concerning gut specifically.

Gamut Music has plenty of quality gut in stock and we are working every day to make sure you have a reliable supply of high quality gut strings.

If you have any questions about the quality and availability of gut, please contact support@gamutmusic.com.

String Economics 101

Regular customers to the Gamut String Store will notice that the prices of strings have recently changed. The prices of the sheep-gut strings have gone up while the prices of the beef-gut strings have gone down. This price change is not due to any quality difference between the two strings, but rather it is because of the different ways in which the raw material is traded and a short explanation might help clear up some confusion about the price structure.

Sheep-gut is traded on an international market as a commodity like oil, precious metals, etc. The material originates in some country like New Zealand or Australia and sold to brokers who have contracts with the producers. The material is then offered on the international market where it is bid upon by other companies who wish to purchase it for import into their local market. The price of the winning bid is dependent on the strict rules of supply and demand and thus, the price of the material can swing widely to the end buyer as the market ebbs and flows.

As we have been told by our supplier, two events have conspired recently to drive up the cost of sheep-gut. One has been a drought in Australia that has reduced the available supply of material. The other has been the popularity of a small, spicy sausage in Japan and China. When we first started making strings we chose as our preferred material a size of casing that was not used and valued by the sausage industry and therefore we could purchase this size material for much less than other sizes of casings that were used for sausage. It is unfortunate that this spicy sausage uses the same size that we do and now we have to compete with that industry for material, which drives up the cost and reduces the available supply.

In the last year the cost of this material has more than doubled and left us no choice but to raise the price of the resulting strings. More than that, the supply has become restricted and uncertain. We get our material from only one supplier in New Zealand, which is the only source that meets our standards of quality. We have purchased up all of this material that is available and our supplier is not sure when more will be coming in, but it will certainly be many months. We have enough stock on hand for quite a while to insure the availability of quality strings and assume that the market conditions will correct themselves in due course, but you will notice that the price of sheep-gut strings has gone up. The prices of thicker strings have gone up more because the cost is dependent on how many gut ribbons go into the construction. Since the number of ribbons increases logarithmically as the diameter increases, the cost of the string increases proportionally.

Beef serosa, on the other hand, has a completely different pricing structure. We purchase the material directly from the producer so there are no middlemen involved in the transaction to drive up the cost. In addition, this material is used only for string making so we don't have to compete with other industries for the supply. The result is a much lower cost that is not subject to the whims of a temperamental market. Also, the beef serosa is available in different widths so we can purchase a wider material that has more mass that can build up the larger diameters of gut faster and thereby reduce the cost of labor, as well. All factors considered, beef serosa is a more economical material than sheep-gut and we have restructured the string prices to reflect this.

Sheep-gut is not the only string making material that has gone up in price. Since the economy of the USA and other countries has been fragile for so long now, many people have been purchasing precious metals as an investment and as a way to shelter money. This trend has caused the price of silver to almost double in the last year, resulting in our need to raise the price of silver-wound strings. Each time we have to purchase silver wire for strings we have to pay more for the material, as we have to purchase it on the open market and whatever the price of silver is that day is the price we have to pay.

At Gamut we are committed to offering strings to a wide range of clientele, so for those musicians who do not feel the need to make the expense of a sterling silver string we offer strings wound with nickel silver and copper wires as well as a string with one wire of silver and one wire of copper. There should be a wound string in our catalog for every price point.

New Beef Gut Strings

Gamut Music has been known as a maker of sheep-gut strings for many years. Historical sources often mention sheep gut as a material, but other sources were used for string making, as well. For the last eight months we have been working with beef serosa, learning how to use it and refine the processing for this material. The material we use comes from Ireland and is taken from the small intestine of the animal, (like the sheep material), but instead of the whole intestine being used as with sheep, ribbons are cut from only one side of the cattle material where the muscle fibers are the strongest and most pure.

The customer feedback we have received indicate that beef gut stabilizes more quickly and holds pitch a little better than sheep gut. The tone has been described as being clearer and brighter than sheep but of equal gauge.

Beef serosa has a higher tensile strength than does sheep gut, so strings from this material are useful for instruments that require extra durability. For example, if your instrument has a longer string length which puts beyond the comfortable range for gut strings, the beef gut would be a good choice for string material as it will stand the strain a little better.

Beef gut is available as standard length, (120cm, 48"), treble gut available with either a natural or varnish finish. Natural strings are hand-rubbed with a light oil. Varnished strings have three coats of finish before being hand polished with the oil. This gut is available only in the natural color which varies from white to a pale straw hue.

Gamut beef gut strings are available in diameters of .38mm to .80mm and are considered special-use strings for instruments that require a stronger gut.

Like the Treble gut, Beef gut is processed to be a little harder than the other kinds of gut and also has a lower twist of about 15 degrees to increase the strength and is an ideal string for:

Violin: e-1 and a-2

Viola: a-1

Bass viol: d-1

Tenor viol: g-1

Treble viol: d-1

Lute: g-1, d-2, a-3, and octaves on bass courses

Harp: treble strings