TL;DR: With the increased demand for Gamut gut strings, ordering as much in advance as possible will be the best practice.

As you may know, substantial changes in the supply chains and general economy in the last few years have affected all businesses. In addition, the music string industry has suffered from some production workshops closing. These changes mean that there is an unprecedented demand for our products at a time when material is both difficult and expensive to come by.

With this "new normal," there are simply no strings "on-hand," as everything made is being shipped immediately. Additionally, please understand that due to the logistical constraints in the string workshop, it is not possible for us to offer expedited string services.

At Gamut Music, we operate at "the speed of gut," meaning that individual orders are processed as they come in, as soon as materials become available from the gut room. Unfortunately, this process cannot be accelerated without compromising the high quality of our hand-made natural gut strings.

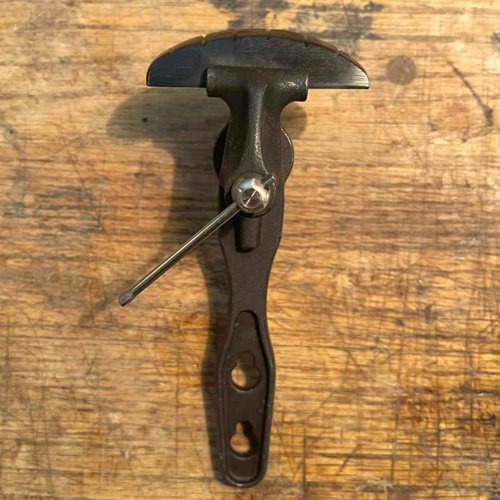

The nature of our hand-crafted strings requires time for the gut to be meticulously split, cut, processed, whitened, twisted, seasoned, dried, and polished or wound. Contrabass strings, for instance, take over six weeks to complete from start to finish. However, rest assured that our workshop is continuously in the process of creating more strings.

We hope to return to a point of building up a stock of on-hand strings, but this will depend on the continued influx of new orders.

We send a sales receipt with tracking # when your order leaves the workshop.

Kind regards,

Dan Larson and the Gamut Music workshop